Potential Worker Safety Hazards Grow in Budding THC/CBD Oil Extraction Processing Industry

Gas Hazards

Solvent Extraction is used to remove the essential oils from plant matter which is then distilled to separate it into the desired compounds and remove the solvent. Common process “solvents” include Ethanol, other flammable liquids, Butane and Carbon Dioxide. Most are toxic and highly flammable while CO2 is toxic and can cause asphyxiation.

Flammable solvents require storage, piping, valves and controls for proper process operation and safety. Monitoring flammable and toxic gases is mandatory per regulation. CO2 is another common hazard at these sites coming from cylinders or a gas burning generator. Monitoring for Carbon Monoxide (CO), Carbon Dioxide (CO2), and Natural Gas or Propane is required when a generator is use.

How to Monitor to Improve Worker Safety and Comply with Ordinances

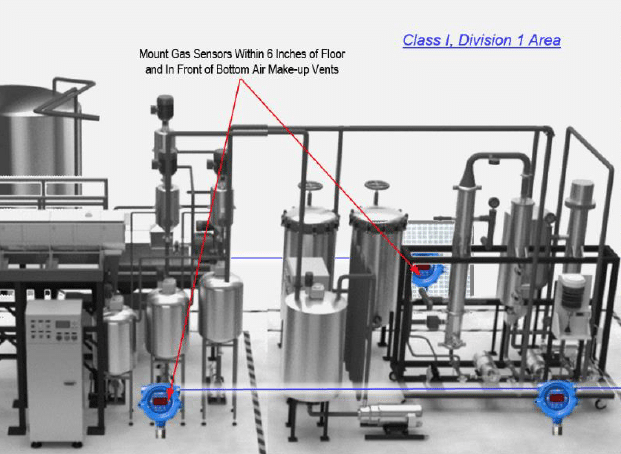

Building and safety regulations specify the use of gas detection to be installed in specific areas based on gases to be monitored and the area hazard classification. Codes call for bottom air make-up ventilation and a listed gas detector within 12 inches of the lowest point for flammables. Detectors are often placed in front of the exhaust ventilation grills and on the process equipment near the potential leak points. CO2 is monitored in the waist to face zone as it is a breathing hazard but heavier than air.

Local annunciation may be employed and gas detection alarm contacts interlock with other devices and AC power to shutdown the process if an alarm is higher than 25% LFL. Ventilation fans are activated by a gas alarm of 10% LFL or higher. Indoor gas storage and solvent recovery areas require their own gas detectors and ventilation.

| CAS No. |

Name | OSHA PEL 8 Hr. TWA |

ACGIH STEL 15 Min. |

NIOSH IDLH 30 Min. |

LFL %Vol |

Flash Point °F/°C |

Vapor Density Air = 1.0 |

|---|---|---|---|---|---|---|---|

| 124-38-9 | Carbon Dioxide |

5,000 ppm | 30,000 ppm | 40,000 ppm | Non- flammable |

– – | 1.5 |

| 64-17-5 | Ethanol | 1,000 ppm | 1,000 ppm | 3,300 ppm | 3.30% | 57° / 14° | 1.5 |

| 106-97-8 | Butane | 800 ppm | 1,000 ppm | 1,600 ppm | 1.80% | Gas | 2.1 |

| 67-63-0 | Isopropyl Alcohol |

400 ppm | 400 ppm | 2,000 ppm | 2.00% | 53° / 12° | 1.05 |

| 142-82-5 | Heptane | 400 ppm | 500 ppm | 750 ppm | 1.10% | 25° / -4° | 3.5 |

| 110-54-3 | Hexane | 500 ppm | 50 ppm TWA | 1,100 ppm | 1.10% | -7.6° / -22° | 3 |

| 108-88-3 | Toluene | 200 ppm | 300 ppm Ceiling | 500 ppm | 7.10% | 40° / 4° | 3.1 |

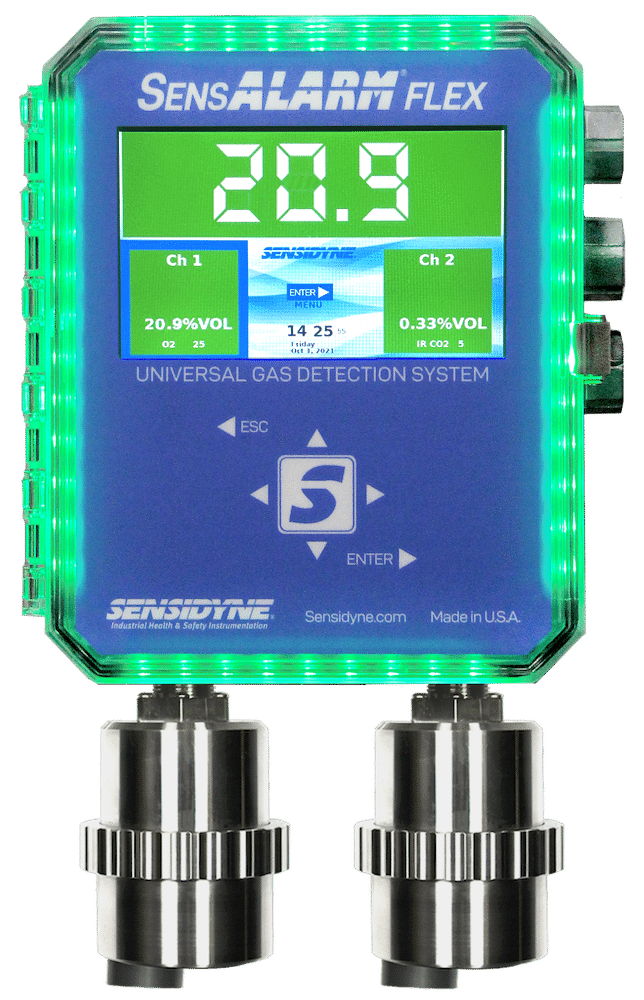

Sensidyne Gas Detection for Cannabis Facilities

Sensidyne has decades of experience in manufacturing fixed gas detection and we pioneered intelligent gas sensors and universal transmitter in the 1990s. Customers rely upon our high quality products for asset protection and personnel safety. The staff has decades of experience in process, industrial, manufacturing and HVAC applications and should be consulted for specific solutions to dangerous gas exposure and compliance issues.

Founded in 1983, Sensidyne is ISO 9001: 2015, EN 13485: 2003 certified. Fixed gas detection has global approvals for hazardous (classified) areas, SIL 2, sensor performance certifications, CE Mark, and RoHS. Every team member is charged with delivering products and solutions that are effective and robust for customer satisfaction.

Sources:

OSHA 29 CFR 1910.1000 Table Z-1 Limits for Air Contaminants l PEL: Permissible Exposure Limit as an 8 Hour TWA ACGIH: American Conference of Governmental Industrial Hygienists

NIOSH IDLH: Immediately Dangerous to Life or Health, The National Institute for Occupational Safety and Health California Fire Code: Chapter 38 Plant Processing and Extraction Facilities

2018 IFC, The International Fire Code l NFPA 1, The Uniform Fire Code l NFPA 70, The National Electrical Code NFPA 30, The Flammable and Combustible Liquids Code l NFPA 58: The Liquefied Petroleum Gas Code

UL 1389, Outline of Investigation for Plant Oil Extraction Equipment