Below are excerpts from a recently published article MONITORING COMBUSTIBLE AND TOXIC GASES IN INDUSTRIAL ENVIRONMENTS: AN OVERVIEW

In survival situations the rules of three apply: three weeks without food, three days without water and three minutes without air – are all deadly. Clean air is vital for human health and must be stringently monitored in industrial environments where toxic, corrosive, asphyxiant and combustible gas hazards are common. In food & beverage plants, anhydrous ammonia is used as a refrigerant. Hydrogen sulfide can accumulate in sewage systems of wastewater treatment centers. And carbon monoxide from engine exhaust fumes can accumulate in fuel tank filling stations. These are all examples of toxic gas hazards that can be monitored using electrolytic sensors that we will cover in this article…

Gas Detection Systems

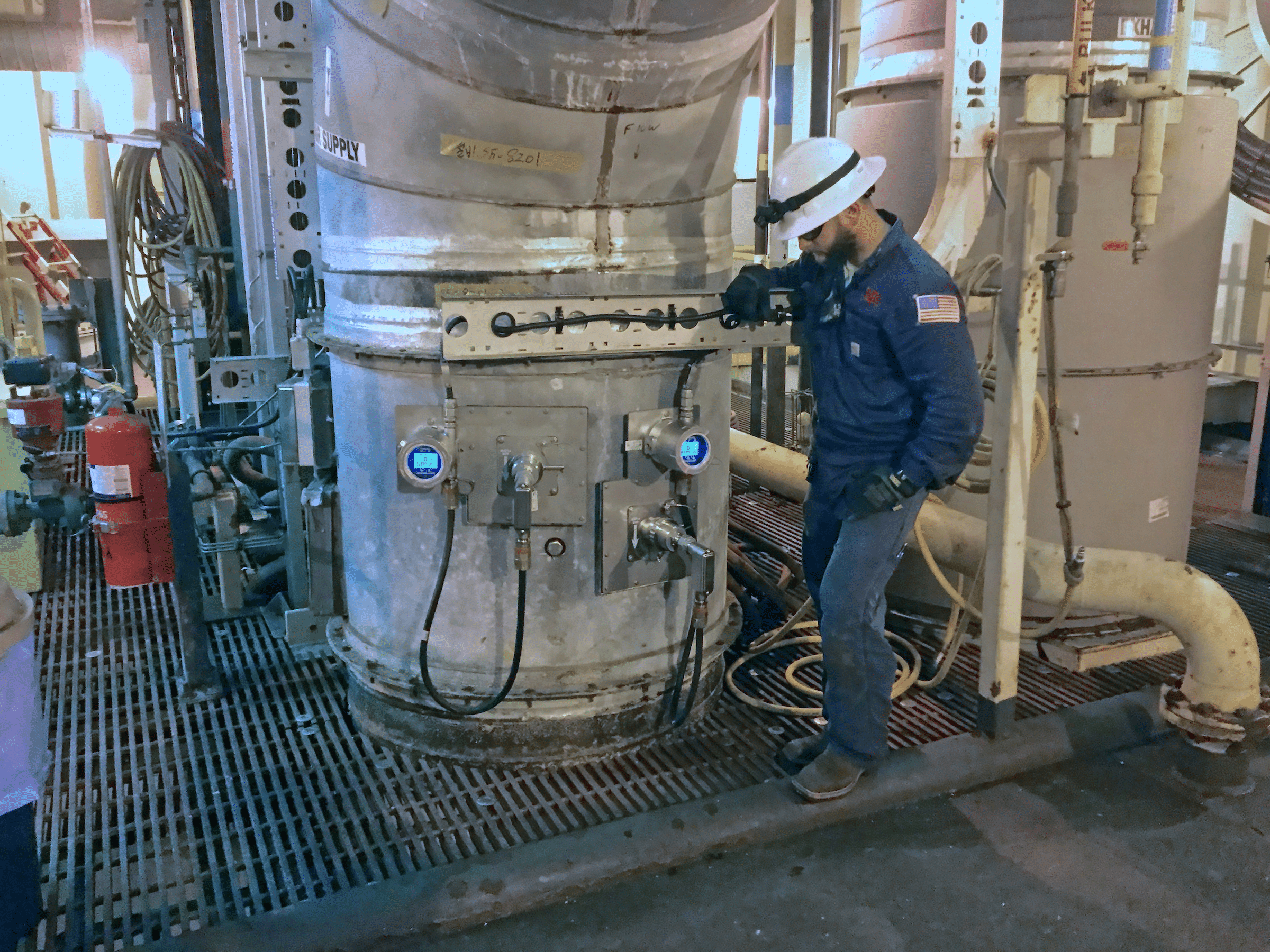

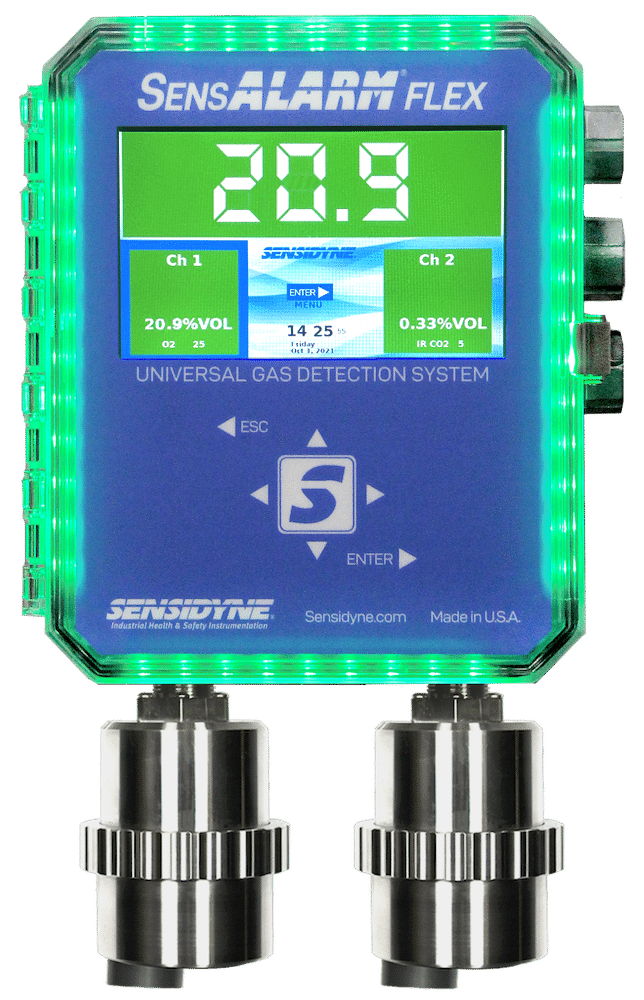

Gas detections systems are put in place to alert workers of hazardous conditions such as toxic, corrosive and asphyxiant gas reaching harmful concentrations and combustible gas leaks reaching their lower explosive limit (LEL). Sensidyne Fixed Gas Detection systems consist of a sensor and transmitter which are installed in a fixed location in close proximity to the potential hazard source…

Read further in the complete article:

Types of Detection Covered

- Asphyxiant and Toxic Gas Hazards: Electrolytic Sensors

- Combustible Gasses and CO2: Infrared Sensors (IR)

- Photoionization: Volatile Organic Compounds

- Combustible Gases: Catalytic Bead Sensors

“The Basics” Topics Covered

- Lower Explosive Limit

- The Transmitter

- Calibration

- K Factors

- Area Classification

- Sensor Placement

- Sample Draw